Provide the best solutions

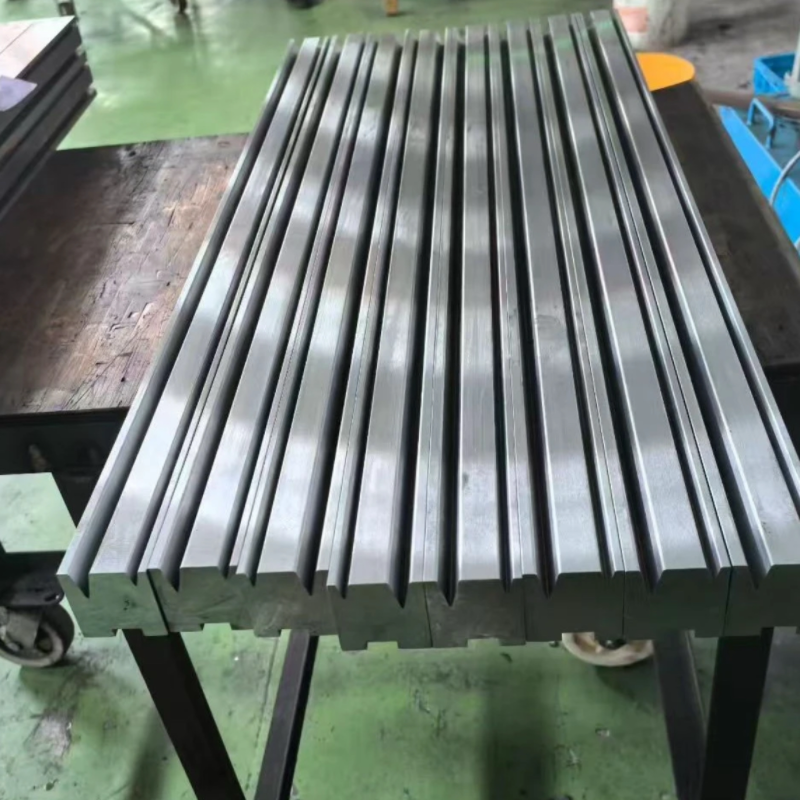

As a leading exporter of CNC press brake dies, forming dies, clamping systems, and laser welding and marking machines, IVILA provides high-quality solutions worldwide from our state-of-the-art facilities in China.

Hot Products

Why Choose Us?

Strict Quality Control

Safe packaging and fast delivery

Professional Solutions

Quality Assurance

Technical and Service Support

Professional Certification

Products Display

Laser Marking Machine

Laser Welding Machine

Customer Testimonials

Contact Us

Press Brake Tooling FAQ

The press brake punch is a critical component of a press brake, typically installed on the upper beam or ram of the press brake. It directly participates in the metal sheet bending process by pressing down in conjunction with the press brake die, causing the sheet to undergo plastic deformation according to the preset angle and shape. The precision and shape of the press brake punch directly affect the quality of the bent parts.

Press brake tooling can be categorized into two main types based on application needs and processing materials: - Standard Press Brake Tooling: Suitable for common bending angles and shapes such as 90 degrees, 45 degrees, 30 degrees, and 19 degrees. - Custom Press Brake Tooling: Designed and manufactured according to specific customer requirements to meet non-standard or special bending needs.

Common materials for press brake punches include high-strength alloy steel, carbide, and tool steel. These materials offer excellent wear resistance, hardness, and deformation resistance, allowing them to withstand high loads and temperatures during the bending process, ensuring bending precision and tooling longevity.

The delivery time for custom press brake tooling varies depending on the tooling complexity, manufacturer production capacity, and raw material availability. Generally, simple press brake tooling may take a few weeks to a month, while more complex tooling may take longer to design and manufacture. It is recommended to communicate the delivery time with the supplier in advance and allow sufficient time to ensure the production schedule is not affected.

When selecting press brake tooling, consider factors such as sheet material, thickness, bending angle, shape complexity, and production efficiency. Our tooling options are diverse, ranging from standard V-shaped tooling to complex multi-station tooling, catering to various processing needs. It is advisable to communicate your specific requirements with our sales or technical support team to get the most suitable recommendation.

The material of press brake tooling directly impacts its wear resistance, hardness, and toughness, which in turn affects processing performance and tooling lifespan. Common materials for press brake tooling include high-strength alloy steel and carbide, which offer excellent wear resistance and deformation resistance, ensuring high precision and surface quality of the bent parts.

When replacing and adjusting the press brake punch, ensure the equipment is powered off and in a safe state. Follow the equipment operation manual to step-by-step remove the old press brake punch and install the new one. During adjustment, carefully calibrate the relative position between the press brake punch and the press brake die to ensure the gap and angle meet the process requirements. Additionally, check the tightness of the fasteners to prevent tooling damage or safety accidents due to loosening.

Yes, we provide comprehensive after-sales service support, including installation and commissioning of press brake tooling, operational training, troubleshooting, and regular follow-up visits. If you encounter any problems or need technical support during use, please contact our customer service team or sales personnel, and we will be happy to assist you.

To extend the service life of the press brake punch and maintain its optimal working condition, it is recommended to regularly perform the following maintenance and upkeep tasks:- Cleaning: Regularly clean the surface of the press brake punch to remove oil, iron filings, and other impurities, keeping the tooling clean. - Lubrication: Regularly lubricate parts that require it to reduce wear and friction. - Inspection: Regularly inspect the wear condition of the press brake punch, the tightness of fasteners, and the connections of all parts. Address any issues promptly.- Storage: When not in use, store the press brake punch properly in a dry, ventilated, dust-free environment to prevent moisture, rust, or damage.

Yes, we offer comprehensive custom services. Whether you have special sheet material types, bending angles, or shape requirements, our professional team can design and manufacture suitable press brake tooling based on your specific needs. We are committed to meeting our customers' individual requirements and ensuring perfect results in every processing task.

The press brake punch is a key component of the press brake. Its primary function is to work with the press brake die to apply pressure, causing the metal sheet to bend and deform according to the predetermined angle and shape. The precision and design of the press brake punch directly determine the quality and accuracy of the bent workpiece.

Our press brake tooling is suitable for a wide range of metal materials, including stainless steel, aluminum sheets, iron sheets, and copper sheets. We can also customize tooling to suit special materials according to customer requirements.

The suitable materials for the press brake punch depend on the type, thickness, and bending requirements of the sheet being processed. Generally, high-strength and wear-resistant alloy steel is commonly chosen because it can withstand high pressure and repeated use without easily getting damaged.

The choice of V-groove angle depends on the desired bending angle and the thickness of the sheet material. Our sales personnel and technical support team can provide professional advice based on your specific needs to help you choose the most suitable V-groove angle.

To extend the service life of the press brake punch, regular maintenance and care are essential. Specific measures include: - Keeping the surface of the press brake punch clean to avoid accumulation of oil and iron filings. - Regularly lubricating the sliding parts of the press brake punch to reduce friction and wear. - Checking the fasteners of the press brake punch to ensure they are not loose, and tightening them if necessary. - Avoiding using the press brake punch for bending operations beyond its design range to prevent overload damage.

The lifespan of the tooling is influenced by various factors, including material quality, usage conditions, and the type and thickness of the processed sheet material. We use high-quality materials and advanced manufacturing processes to extend the tooling's lifespan. Proper usage and regular maintenance are also key factors in prolonging tooling life.

When the press brake punch shows signs of wear or damage, first assess the extent of the wear or damage. If it is only minor wear, it can be repaired through grinding or polishing. If the wear or damage is severe and affects the precision and quality of the bent parts, it is necessary to replace the press brake punch promptly. During replacement, ensure the new press brake punch's specifications, model, and material match the old one, and follow the correct steps for installation and adjustment.

Yes, we offer repair and refurbishment services for tooling. If your tooling shows signs of wear or damage, please contact our after-sales service department, and we will provide professional repair and refurbishment solutions.

Improving the bending accuracy of a press brake punch can be approached in several ways: - Ensure the manufacturing precision and installation accuracy of both the press brake punch and press brake die. - Set and adjust the gap and angle between the press brake punch and press brake die appropriately during the bending process. - Use advanced CNC technology or servo control technology to accurately control the movement trajectory and speed of the press brake punch. - Regularly calibrate and maintain the press brake to ensure consistent accuracy.

We strictly follow ISO quality management system standards for production and quality control to ensure each set of press brake tooling meets quality requirements. Before leaving the factory, our press brake tooling undergoes rigorous testing and calibration to ensure accuracy and stability. We also accept on-site inspections by customers to ensure the tooling meets their expectations and requirements.